TAILORED

One of Fytisa’s specialties is the design and production of customised and tailored Nonwoven Fabrics according to the requirements of our clients.

Our R&D team collaborates with the client in all the stages of the product development until it is approved.

MORE INFORMATION

- WEIGHTS

- TECHNOLOGY

- FINISHES

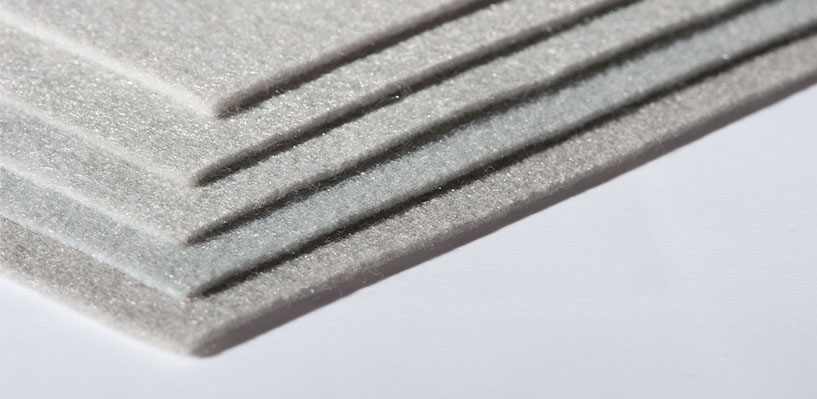

WEIGHTS

WEIGHT

De 80 g/m2 a 800 g/m2

TECHNOLOGY

PUNCHING

The bonding process of Nonwoven fabrics is made mechanically through the action of the needles that sew the layer, with no use of chemical bonding.

FINISHES

VELOUR

This process uses punching technology to obtain a soft and velvety surface. The Velour developed by Fytisa maintains the look after undergoing a process of pressure, temperature and handling.

CALENDERING

We can apply calendering to our Nonwoven fabrics (applying colour and pressure at the same time).

PRINTING

We offer customised, as well as Fytisa designs.

HOT MELT APPLICATION

We can apply hot melt dust (HDPE, LDPE, PES, CoPES,…) to our Nonwoven fabrics.

IMPREGNATION

We can obtain any especial feature that our clients may require

ECORESISTANT

This finish provides high resistance to abrasion and rubbing.

The finish is free of PFOA, PFOS and formaldehyde.

ECOCLEAN

EcoClean is a finish that facilitates the cleaning of the Nonwoven in front of the effect of liquid and/or solid agents, such as oil, grease, chocolate, etc.

The finish is free of PFOA, PFOS and formaldehyde.

ECOCARE

This finish combines the features of the eco-clean and the eco-resistant, while maintaining both of their benefits.

The finish is free of PFOA, PFOS and formaldehyde.